Knee Replacement

Knee replacement is one of the most successful orthopedic surgeries performed today. Most patients experience reduced or eliminated knee pain, increased ability to move and an overall improvement in quality of life.

HSS performs more total knee replacement surgeries than any other US hospital. HSS surgeons invented the first modern total knee replacement in the 1970s and have continually improved surgical techniques, technology and prosthetic materials ever since. In 2020, HSS became the first hospital in the United States to complete a total knee replacement using augmented reality (AR) assistance.* A wearable AR headset improved the surgeon's view to facilitate precision cuts and implant positioning down to a single millimeter.

What is knee replacement surgery?

Knee replacement is where portions of the bones that form the knee joint are removed and replaced with artificial implants. It is performed primarily to relieve knee pain and stiffness caused by osteoarthritis.

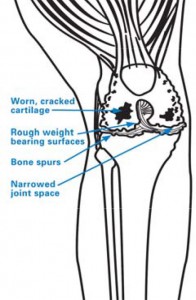

Most people who get this surgery have advanced knee arthritis, in which the knee cartilage is worn away and the surface of the knee becomes pitted, eroded, and uneven. This causes pain, stiffness, instability and a change in body alignment. Knee replacement surgery can also help some people who have a weakened knee joint caused by an injury or other condition. (Find a knee replacement specialist at HSS.)

What are the different types of knee replacement surgery?

There are two main types:

- total knee replacement, where the entire joint is replaced with artificial surfaces

- partial knee replacement, where only one damaged compartment of the knee is replaced

Total knee replacement is the more common of these two procedures.

Knee anatomy

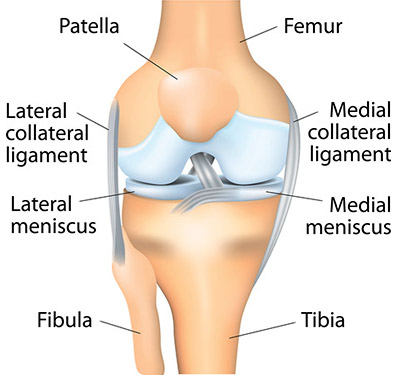

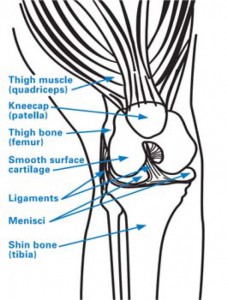

To understand a total knee replacement, also known as total condylar knee arthroplasty, you must be familiar with the structure of the knee, a complex joint that consists of three bones:

- the femur (thighbone)

- the tibia (shinbone)

- the patella (kneecap)

Strong ligaments connect the powerful muscles of the thigh and calf to the bones around the knee to control knee motion and function. Cartilage (such as the meniscus) and other soft tissues cover and cushion the bones to help them glide together smoothly.

When you bend or straighten your knee, the end of the femur rolls against the end of the tibia, and the patella glides in front of the femur.

When the cartilage that cushions the joint degrades or is worn away completely, the bones rub together and become scraped and rough. This causes inflammation known as osteoarthritis, which results in pain and stiffness that make walking and other movement difficult. The implants used in knee replacement are smooth like the surfaces of a healthy knee.

How is a total knee replacement performed?

First, the orthopedic surgeon makes an incision (cut) in the knee and moves the patella (kneecap) to the side. If any bone spurs (small bony growths) are present, as sometimes occurs in osteoarthritis, they will be removed.

Next, the two menisci between the femur and tibia are removed, as are the anterior cruciate ligament (ACL) and, in some cases, the posterior cruciate ligament (PCL). In some types of knee replacement, the PCL is retained.

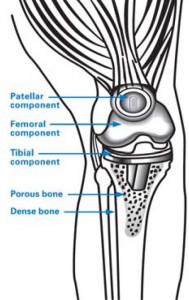

During the main phase of the operation, the surgeon cuts and removes cartilage and some bone from the upper part of the tibia and lower sections of the femur. The femoral sections removed are two knobby protuberances called the femoral condyles. The tibia and femur are then capped with metal implants to create new surfaces for the joint. The surface of the femoral component mimics the shape of the original femoral condyles. If the kneecap has also degraded, the surface on its underside may also be cut away and replaced with a polyethylene implant.

Finally, the various layers of tissue are repaired with dissolvable sutures and the skin incision is closed with sutures or surgical staples. A bandage will be wrapped around the knee and the patient is taken to recovery.

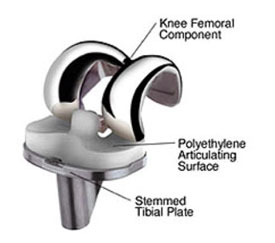

Fixed-bearing knee implant with a polyethylene articulating surface (plastic tray) sandwiched between the metal tibial implant and metal femoral implant.

Side-view illustration of a knee with a fixed-bearing knee implant in place.

X-ray of a knee after total knee replacement, showing the implanted prosthesis)

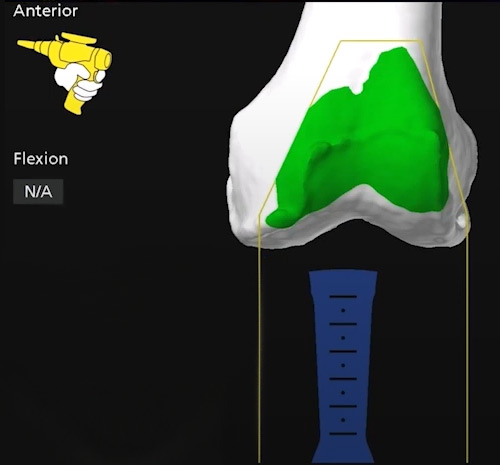

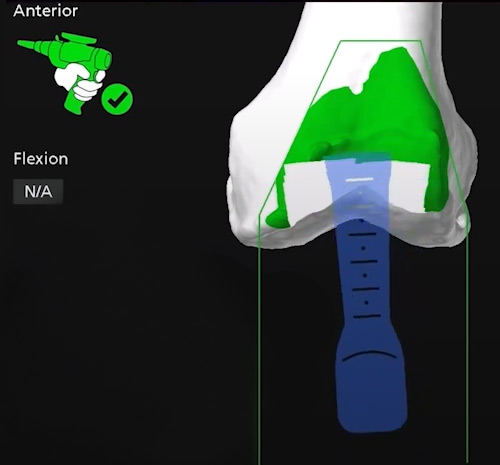

In some cases, the orthopedic surgeon may employ robotic technologies during the operation. (Find an HSS surgeon who performs robotic-assisted, knee replacement.)

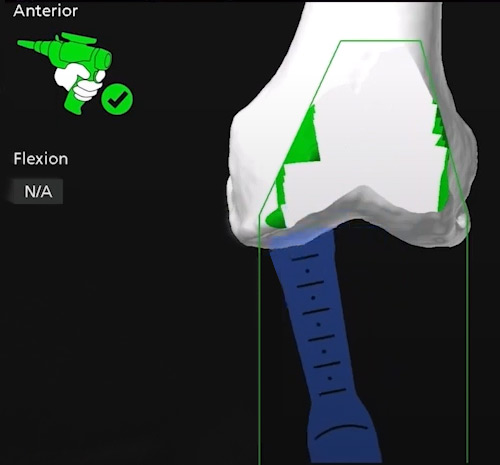

Real-time computer navigation image of a robotic arm used by an orthopedic surgeon on the front of the femur, prior to osteotomy.

Real-time computer navigation image of the robotic arm at the start of the osteotomy to remove bone from the front of the femur.

Real-time computer navigation image of the robotic arm near completion of the knee osteotomy to prepare the femur for an implant.

What kind of anesthesia is used in a knee replacement?

Most total knee replacements at HSS are performed under regional anesthesia. It is called an epidural block, which is the same kind of anesthesia given to women in labor. The epidural anesthesia provides numbness from the waist down, so there will be no pain during surgery. In addition, patients are given a light sedative to make them as sleepy or awake as they want to be.

What are knee replacement implants made of?

The selection of knee replacement prosthesis design and materials depends on each individual patient. The main implant components are made of metal – usually titanium or chrome-cobalt alloys. The implants are fixated in place either with a cement bonding agent or by osseointegration, in which a porous metal stem extends into the tibia and the patient's natural bone grows into it. A plastic platform or spacer will be inserted between the tibial and femoral implant surfaces. The spacer is made of polyethylene.

Most femoral components are made of metal alloys (cobalt chromium) or metal-ceramic alloys (oxidized zirconium). The patellar component is plastic (polyethylene). The tibial insert component is also plastic (polyethylene). The tibial tray component can be made of the following materials:

- cobalt chromium (metal alloy)

- titanium (metal alloy)

- polyethylene (plastic)

Video: Animation of a total knee replacement

Partial knee replacement overview

A partial knee replacement is also known as unicompartmental knee arthroplasty or unicondylar knee arthroplasty. In this surgery, damaged cartilage and bone are removed and replaced only in one diseased compartment of the knee. This differs from a total knee replacement, in which bone and cartilage from the entire joint are replaced.

Partial knee replacement is suitable for people who experience arthritis only in one compartment (section) of the knee joint, rather than throughout the joint. It can also provide relief from pain and stiffness in some people who have medical conditions that make them poor candidates for total knee replacement surgery.

How do I avoid or postpone a knee replacement?

The choice on whether to have surgery to address arthritis of the knee joint depends on multiple factors, including:

- the condition of the knee joint

- the patient’s age and activity level

In cases where the damage from arthritis is minimal, and/or if the patient does not have a very active lifestyle, nonsurgical treatments by be tried, including:

- physical therapy

- NSAIDs (nonsteroidal anti-inflammatory drugs), such as ibuprofen

- weight loss to reduce pressure on the knee

How do I know if I need knee replacement surgery?

You may need surgery if:

- Your knees are stiff and swollen.

- There is pain throughout the day, even at rest.

- Walking, getting up or climbing stairs is difficult and painful.

- Medication and therapy do not offer enough relief.

- Knee cartilage is so damaged and worn away that you are walking "bone on bone," in which the bones of the joint are scraping together.

(Find a knee replacement surgeon at HSS.)

How long does a knee replacement last?

Knee replacement implants are expected to function for at least 15 to 20 years in 85% to 90% of patients. However, the implants do not last forever.

After a period of 15 to 20 years, general wear and tear may loosen the implant. Depending on the patient, this may cause no symptoms, or it may cause any of the following:

- pain

- loose implant particles

- knee instability

- infection

When these symptoms arise, orthopedic surgeons recommend having knee revision surgery to replace the original implant. Infection, especially, requires a prompt revision surgery. Infection after knee replacement surgery is rare, but a knee replacement implant cannot defend itself from infection if bacteria are introduced to the body. Learn more about the low infection rates at HSS.

Can knee replacement be done as an outpatient?

Most patients stay in the hospital one or two nights after surgery. Some patients are able to return home the same day after an outpatient procedure. Learn more by reading Outpatient Knee Replacement Surgery: Frequently Asked Questions.

Can both knees be replaced at the same time?

Yes, healthy patients younger than 75 years old, with no cardiopulmonary disease may be candidates for such surgery. Your orthopedist can tell you more about what is involved.

How long does knee replacement surgery take?

Total knee replacement surgery generally takes about 60 to 90 minutes, but you should expect to be in the operating room for over two hours.

How long does it take to walk after a full knee replacement?

Most often, within two or three days after surgery, a patient will be able to start walking with assistance from a straight cane, walker or crutches. The distance and frequency of walking will increase as the days progress.

Patients are usually able to drive a car within three to six weeks after surgery and resume most other normal activities by or before six weeks. Complete recuperation and return to full strength and mobility may take four months or more. However, in many cases, patients are significantly more mobile one month after surgery than they were before they had their knee replacement.

Knee replacement recovery time and recuperation

Rehabilitation (physical therapy) will begin within 24 hours of surgery. After your surgery, the nursing staff will position you in bed and help you turn until you are able to move on your own. You may have a pillow between your legs if ordered by your surgeon.

Very soon after surgery, a physical therapist will come to your room to teach you appropriate exercises and review your progress. Gentle exercises to improve your range of motion can help prevent circulation problems as well as strengthen your muscles.

Your rehabilitation program will begin as soon as you are medically stable and there are orders from your doctor to begin postoperative mobility. All patients begin rehabilitation within 24 hours of their surgery. Your motivation and participation in your physical therapy program is key to the success of your surgery and recovery. The physical therapist will assist you in the following activities:

- sitting at bedside with your feet on the floor

- transferring in and out of bed safely

- walking with the aid of a device (walker, cane, or crutches)

- climbing stairs with aid of a device

Will a knee replacement set off a metal detector?

While knee implants generally do not set off metal detectors, more sensitive machines may register the presence of the implant. Some physicians give their patients cards to show at the airport that explain that the bearer has received a knee prosthesis containing metal.

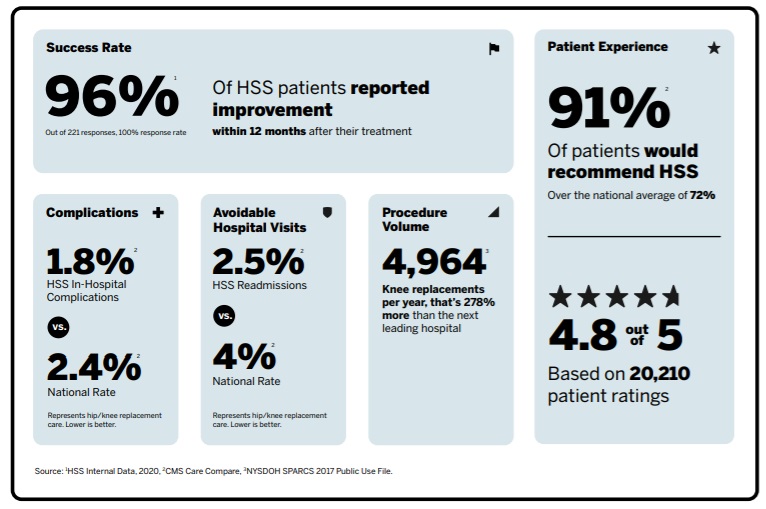

What can I expect at HSS?

Hospital for Special Surgery has been at the forefront of modern knee replacement since the operation was first introduced in the late 1960s. We have led the field ever since in a number of ways:

- The numbers: HSS has been ranked the No. 1 hospital for orthopedics by U.S. News & World Report for 11 years straight.

- Along with high rankings in patient satisfaction, HSS performs the most knee replacements with the lowest reported infection rates in the United States.

- Research and advancement: Smaller incisions, new implant materials and design, and sophisticated instrumentation have been – and continue to be – the areas of expertise of the hip and knee replacement surgeons of the HSS Adult Reconstruction & Joint Replacement Service.

- HSS routinely uses the latest surgical techniques and technology, such as robotic-assisted and computer-assisted surgery.

- Regional anesthesia: Isolating the anesthesia to a particular body area helps avoid the potential problems that may accompany a general anesthetic. These techniques have been developed and refined by the HSS Department of Anesthesiology, Critical Care & Pain Management.

How to prepare for knee replacement

There are certain steps that can improve your recovery time and results. It is important to follow your knee replacement surgeon’s instructions both before and after surgery, as well as that of your rehabilitation therapist’s recommendations. Learn more about preparing for knee replacement by reading Your Pathway to Recovery: A Patient’s Guide to Total Knee Replacement (TKR).

Why you should choose HSS for knee replacement

Knee replacement is a surgery focused on reducing pain and getting you back to the activities you love. But not all hospitals achieve the same results. Some are more reliable than others. With the help of the HSS Hospital Reliability Scorecard, you can make sure you're asking the critical questions to find the hospital that's right for you. Understanding the data points will help you make the best decision for your care.

More about total knee replacement

These articles, written by HSS physicians, who are also instructors at Weill Cornell Medical College, provide more detailed information on total knee replacement surgery and implants.

- How Do You Know if You Need a Knee Replacement?

- Outpatient Knee Replacement Surgery: Frequently Asked Questions

- Expert Advice on Bilateral Knee Replacement

- What Does Life Look Like After a Knee Replacement?

- Revision Total Knee Replacement: Frequently Asked Questions

- New Technology in Hip and Knee Replacement Surgery at HSS

Articles related to total knee replacement

Learn more about related topics, including conditions that may be treated with a total knee replacement, HSS and medical research on joint replacement surgeries and prostheses. These articles are written by HSS physicians and scientists.

- Knee Surgery: High Tibial Osteotomy

- Take-Home Nerve Block Catheter: Improving Pain Relief After Surgery

- Regional Anesthesia and Pain Management Innovations Improve Patient Outcomes

- Partial Knee Replacement: A Treatment Option in Unicompartmental Knee Arthritis

- Prevention of Infections in Total Joint Replacements (Arthroplasty)

- Joint Replacement: Implant Bearing Surface Materials

- Applied Biomechanics at Hospital for Special Surgery

- Surgery for People With Inflammatory Arthritis

Related articles from HSS Move Better Feel Better

HSS Move Better Feel Better features tips on health, mind-body issues, fitness, and injury prevention for adults and children.

Knee replacement clinical trials

Knee replacement clinical trials

Knee Replacement Success Stories

References

- Malkani AL, Roche MW, Kolisek FR, Gustke KA, Hozack WJ, Sodhi N, Acuña A, Vakharia R, Salem HS, Jaggard C, Smith L, Mont MA. New Technology for Total Knee Arthroplasty Provides Excellent Patient-Reported Outcomes: A Minimum Two-Year Analysis. Surg Technol Int. 2020 May 28;36:276-280. PMID: 31732961.

- Memtsoudis SG, Cozowicz C, Bekeris J, Bekere D, Liu J, Soffin EM, Mariano ER, Johnson RL, Go G, Hargett MJ, Lee BH, Wendel P, Brouillette M, Kim SJ, Baaklini L, Wetmore DS, Hong G, Goto R, Jivanelli B, Athanassoglou V, Argyra E, Barrington MJ, Borgeat A, De Andres J, El-Boghdadly K, Elkassabany NM, Gautier P, Gerner P, Gonzalez Della Valle A, Goytizolo E, Guo Z, Hogg R, Kehlet H, Kessler P, Kopp S, Lavand'homme P, Macfarlane A, MacLean C, Mantilla C, McIsaac D, McLawhorn A, Neal JM, Parks M, Parvizi J, Peng P, Pichler L, Poeran J, Poultsides L, Schwenk ES, Sites BD, Stundner O, Sun EC, Viscusi E, Votta-Velis EG, Wu CL, YaDeau J, Sharrock NE. Peripheral nerve block anesthesia/analgesia for patients undergoing primary hip and knee arthroplasty: recommendations from the International Consensus on Anesthesia-Related Outcomes after Surgery (ICAROS) group based on a systematic review and meta-analysis of current literature. Reg Anesth Pain Med. 2021 Nov;46(11):971-985. doi: 10.1136/rapm-2021-102750. Epub 2021 Aug 25. PMID: 34433647.

- McCormick, John. "Augmented Reality Used in Knee-Replacement Surgery in a U.S. First," The Wall Street Journal, Jan. 21, 2021. https://www.wsj.com/articles/augmented-reality-used-in-knee-replacement-surgery-in-a-u-s-first-11611277959.

- Ranawat A.S., Ranawat C.S. (2012) The History of Total Knee Arthroplasty. In: Bonnin, M. (2012), The Knee Joint: Surgical Techniques and Strategies. Paris: Springer. https://doi.org/10.1007/978-2-287-99353-4_63.

- Sousa PL, Sculco PK, Mayman DJ, Jerabek SA, Ast MP, Chalmers BP. Robots in the Operating Room During Hip and Knee Arthroplasty. Curr Rev Musculoskelet Med. 2020 Jun;13(3):309-317. doi: 10.1007/s12178-020-09625-z. PMID: 32367430; PMCID: PMC7251009.